ISO Factory Direct Provide Stainless Steel Membrane Filter System

Overview Product Description Equipment Principle Ceramic membrane, also known as inorganic ceramic membrane, is an asymm

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | YUAN-MF-Q |

| Dimention | Depends on Capacity |

| Construction Area | Depends on Capacity |

| Weight | Depends on Capacity |

| Transportation | by Sea |

| Automatic Level | Automatic Control |

| Quality | Top Level |

| Power | Depends on The Capacity |

| Main Material | SS304 |

| Advantage | Low Consumption |

| Condition | New |

| Transport Package | Seaworthy Package |

| Specification | Customized |

| Trademark | YUAN |

| Origin | China |

| Production Capacity | 100 Sets Per Year |

Product Description

Product DescriptionEquipment Principle

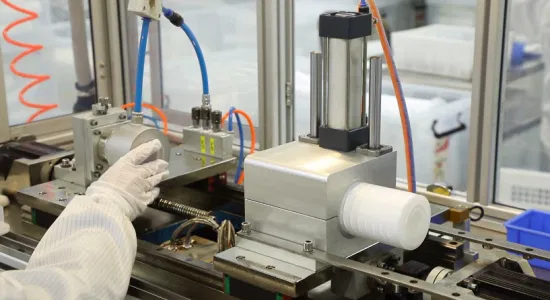

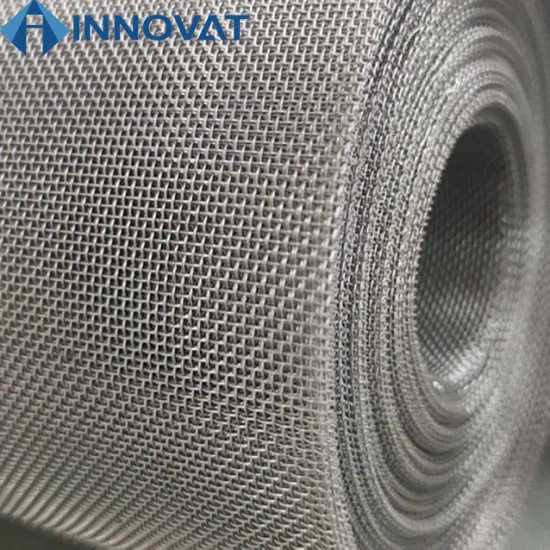

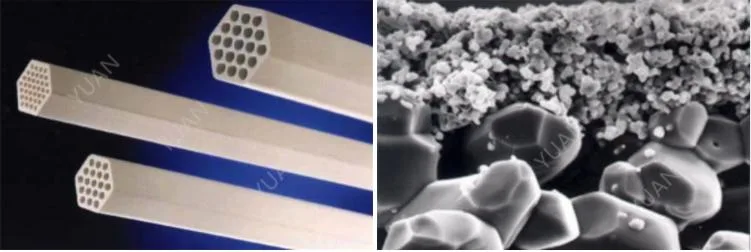

Ceramic membrane, also known as inorganic ceramic membrane, is an asymmetric membrane formed by the inorganic ceramic materials through special processes, which is divided into tubular and flat ceramic membrane. The wall of tubular ceramic membrane is covered with micropores. Under the action of pressure, the raw material liquid flows in the membrane tube or outside. Small molecular substances (or liquid) pass through the membrane, and large molecular substances (or solid) are intercepted by the membrane, so as to achieve the purpose of separation, concentration, purification and environmental

protection.

The wall of flat ceramic membrane is covered with micropores. Different material molecular diameter, different permeability. Driven by the pressure difference on both sides of the membrane, membrane as the filter medium, under the certain pressure, when the material through the membrane surface, only allow the water, salt and small molecules through the membrane, and prevent the suspended solids, glue and microorganisms in the water through.

Product Feature

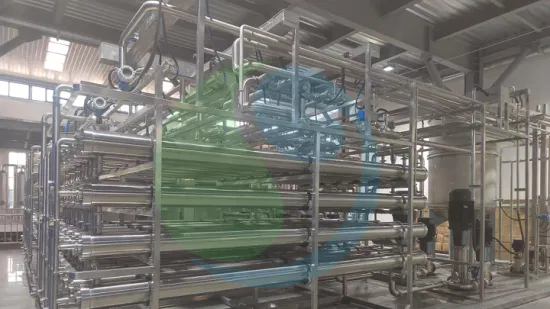

(1)High temp. resistance.(2)Strong anti-microbial ability.(3)High mechanical strength, can be reverse flushing.(4)Good chemical stability. Acid, alkali and organic solvent resistance.(5)The aperture distribution is uniform. High separation efficiency and production yield.(6)Low energy consumption.(7)Good regeneration performance and long service life.(8)Easy operation, stable running and high automatic control.(9)Our team has rich experience in design, technology support, installation & commissioning at site and perfect after-sales service.(10)Customized services, turnkey project, etc. are available for different customers.

Industry Application

* Ceramic membrane has been successfully used in food, beverage, plant (medicine) deep processing, biomedicine, fermentation, fine chemical industry and many other fields, which can be used in the process of separation, clarification, purification, concentration, sterilization, desalting and so on.

* Glucose industries: starch glucose like maltose, glucose, maltodextrin, crystalline dextrose, fructose, F42, F55, crystalline fructose, etc. Xylose.

* Chemical industries: organic acids, including L-lactic acid, citric acid, VC, MSG and various amino acids, like lysine, L-phenylalanine, leucine, methionine, etc.

* Food industries: stevia, sorbitol, xylitol and other sweetners, antioxidant Iso VC sodium, etc.

* Pharmaceutical industries: antibiotics, etc.Detailed Photos

| Country of Origin | China |

| Automatic Level | Automatic Control |

| Main Material | SS304 |

| Voltage | 318V / 220V / Customized |

| Delivery Time | 3-4 Months |

| Installation Time | 20-30 Days |

| Transportation | by Sea |

1.Pre-sale servicesales engineers with professional technical background will provide you with product introduction, process consultation, support of related technical materials and other services. By the experts, professional engineers for you to solve the process, the design and calculation of performance parameters, complete sets of equipment optimization configuration scheme, equipment selection and other services.2.On-sale serviceone-to-one service is provided by the project manager which includes the whole process of ordering, technical contract, design, manufacturing, quality inspection, packaging and transportation, installation and commissioning, operation training, etc.3.After-sale serviceprovide you with relevant product information, file your product construction information, regularly make customer visits, but also provide you with products vulnerable to consumption parts, technical consultation, technical transformation and upgrade services in the use process.4.Field ServiceAfter the equipment arrives at the site, we will send experienced engineering and technical personnel or construction personnel to the site for technical supervision of installation, commissioning and operator training, and responsible for solving the manufacturing quality problems found in the installation, commissioning and trial operation of the contract equipment.5.Respond PromptlyWhen the user requests for on-site service, we will reply within 24 hours after receiving the notice, and arrive at the site with the fastest speed.